Who am i?

About Me

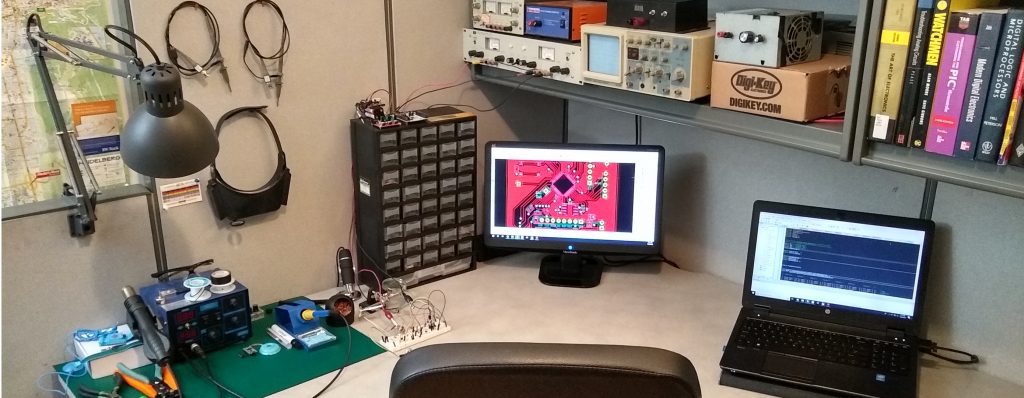

Hello. My name is Aaron Vorse, and I’m an electrical engineer with bachelor’s degrees in both electrical engineering and German studies.

I am infatuated with all things electronic and in my free time I like designing interesting gadgets. My true passion lies in designing embedded systems hardware/firmware, and I always have a project or two under development.

My main skillset includes mixed-signal circuit design, printed circuit board layout, low-level firmware in embedded C, and electronics manufacturing. I’m generally happy with a nice mix of hardware and software.

Skills & Abilities

Circuit Design:

– Mixed-signal systems

– High-voltage/automotive electronics

– LT Spice Simulation

– Board bring-up / debugging

– Sensors, DAC/ADC, signal conditioning

– Comms: I2C, SPI, UART, etc.

PCB Design/Layout:

– High speed

– Design for manufacturing

Light Mechanical Design:

– SolidWorks CAD

Test Equipment:

– Oscilloscope, DMM, function generator, logic analyzer, E-load

Firmware:

– Embedded C

– ARM-based Microcontrollers

Version Control:

– Git/GitHub

Assembly/Rework:

– SMT/THT Soldering

– Custom cabling

Electronics Manufacturing:

– BOM Selection

– Working with contract

manufacturers / fabrication houses

– Designing automated test jigs and procedures

– Root cause analysis

Experience

Lucid Motors

Hardware Engineer/Electrical Test Engineer: 12/2022 – Present

Associate Hardware Engineer/Electrical Test Engineer: 9/2021 – 11/2022

As a result of the Embedded Resume Project, I landed a role at Lucid Motors, a large EV startup that’s pushing boundaries in almost every aspect of the industry. This last nearly year and a half here has been one of the most challenging yet rewarding adventures of my career.

I work primarily on the HV battery management system and have been lucky enough to have had exposure to nearly every aspect of electronics design and manufacturing within the company. My day-to-day generally consists of the following:

- Circuit design, schematic capture, and PCB layout

- Board bring-up, verification, and validation/qualification

- Hands-on bench/system-level testing

- High-volume manufacturing support

- FCT/EOL test fixture/procedure design

- Cross-functional design, debugging, and product planning with software, mechanical, and non-technical team members

- Board and system-level root cause analysis

TechnoTronix

Electronics Manufacturing Technician: 9/2020 – 9/2021

After graduation, I worked at an electronics contract manufacturer to develop my skill set and set me up for my future as a design engineer. I loved working there, since the exposure to an enormous number of engineering projects allowed me to build my knowledge base quickly. Some skills I used were:

- Electrical/mechanical assembly

- Interpreting schematics, assembly drawings, testing docs, bill of materials, and gerber files

- Creating custom cabling and wire harnesses

- PCB shaping, conformal coating, and complex modification

- Board flashing and initial/final product testing in accordance with customer specifications

I also worked with clients to help set up and verify their production text fixtures in addition to identifying and mitigating problems that crop up during production. It was not uncommon for me to have an engineer on the phone, gerber files open, and a multimeter in my hand helping carry out root cause analysis.